-40%

Davis Bros. Unique Custom Collectible #4B Handmade Woodcarving Crooked Knife

$ 11.88

- Description

- Size Guide

Description

Hello friends,This is a new Davis Brothers knife, a traditional Wood Carving #4 B bend (moderate

bend at front of blade) Crook Knife

.

These crook knives are some of the smallest we make, and are excellent for small and even miniature work.

Crook knives are a specialty in the Pacific Northwest and are usually pretty hard to find, mostly made only by custom knife-makers. I'm pretty sure you won't find many, if any, others readily available.

This crook knife is based on designs used by carvers for hundreds of years. Crook knives are extremely versatile and will perform a multitude of tasks well.

WORKMANSHIP: Each knife is unique and hand crafted, with no automated processes used in the more than 30 machining, forging and woodworking tasks for each one. Some tool marks may be visible on the knives. I do not attain absolute machine-like perfection, but strive to combine art, beauty and utility. The look and feel of this tool when held is beautiful, smooth, and inspires the work at hand.

BLADE: It was made using 1095 high carbon blade steel, ground to shape then forged, bent, refined and hardened. It was then tempered to keep a durable, keen edge and is extremely sharp.

HANDLE: The handle is Sapele from Africa with a rich red-brown color and iridescent grain patterns, for a striking appearance.

This handle style has a really nice feel in your hand, and allows plenty of force to be used while still maintaining accurate control. It is finished with hand rubbed Shellac, a benign finish that accents the color and grain and is very durable.

CONSTRUCTION: This knife is 7" overall, with a 1 1/2” long blade that tapers from 3/8

" over the length of the blade before coming to a point. The blade is set with epoxy and further secured with two bronze pins.

CARVING CHARACTERISTICS: I have used knives similar to this for many years, and find them to be very useful for small and miniature scale work. This blade excels at delicate work. The B

bend is curved moderately at the front part of the blade, and works well for hollowing and curved work. It is also great for shaving and texturing on a small scale,

and can take a very fine shaving when needed.

It is meant for use on small relief carving, sculpture, or general hobby uses. Walking sticks and small figures are an example.

It can be used with a wide variety of woods and carving styles. With a single bevel edge all the way around, this knife can be used with either hand, and cuts well either pushing or pulling.

The blade has plenty of strength for those tasks, but should not be used for prying. Be especially careful of the fine tip. For best performance, when sharpening this tool it is important to leave the back side absolutely flat (no bevel on back side).

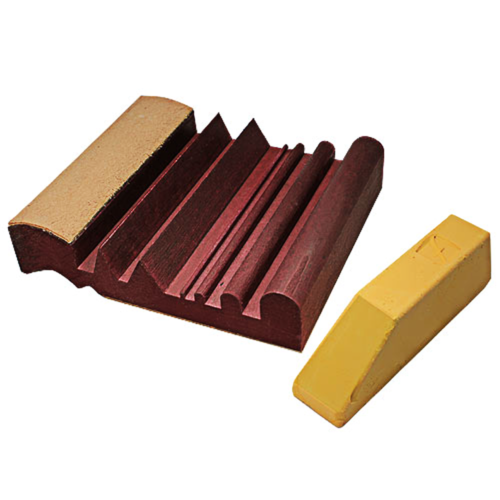

SHARPENING CROOK KNIVES: Every carver will develop their own methods and preferences, but having been asked many times, I will share some suggestions. In general, the same tools and implements used for gouges will get the job done on Crook knives, and most carvers will already have some or all of the items needed. These knives hold an edge well and should go through many many stroppings before needing to be honed.

Stropping the curved edge of a crook knife requires a curved strop. I use a couple that work great and are easy to make:

1) A closet dowel 1 1/4" diameter and about 1 1" long covered with smooth leather carefully glued in place.

2) A smaller, 3/4" dowel, covered with denim cloth ( which holds compound well) glued on.

I use white polishing or buffing compound on both (available in hardware stores or online).

Strop away from the edge, not towards it, and repeat 10 or 20 times or until the keen edge is restored. Strop only the top side ( the beveled side) to maintain the flat bottom side of the blade. If the bottom of the blade needs stropped eventually, then use leather on a flat surface.

Hone the blade only when absolutely necessary, if stropping no longer restores the edge. Use only very fine or ultra fine abrasives. As before, they must be rounded or curved. I use ceramic files, diamond hones, natural Arkansas slipstones and waterstones. All work, but keep them very fine to avoid scratches on the edge. Once again, touch up the flat bottom of the blade only enough to remove a wire edge if it forms when honing. Follow up any honing with a stropping to polish the edge.

SAFETY FIRST! : This blade is extremely sharp. Always be aware of where you are cutting, and do not put hands, fingers or other parts of your body in the path of the blade. Always wear a cut-resistant carving glove on the hand not holding the knife. And please keep this knife safely away from children.

SHIPPING AND CUSTOMER SERVICE: I have several auctions running this week , and will gladly combine shipping to save you money. Wait for the combined invoice if you have multiple purchases/wins. I offer a 30 day return policy and will personally work to resolve any issues. I strive for Quality and Customer Satisfaction